Product Features

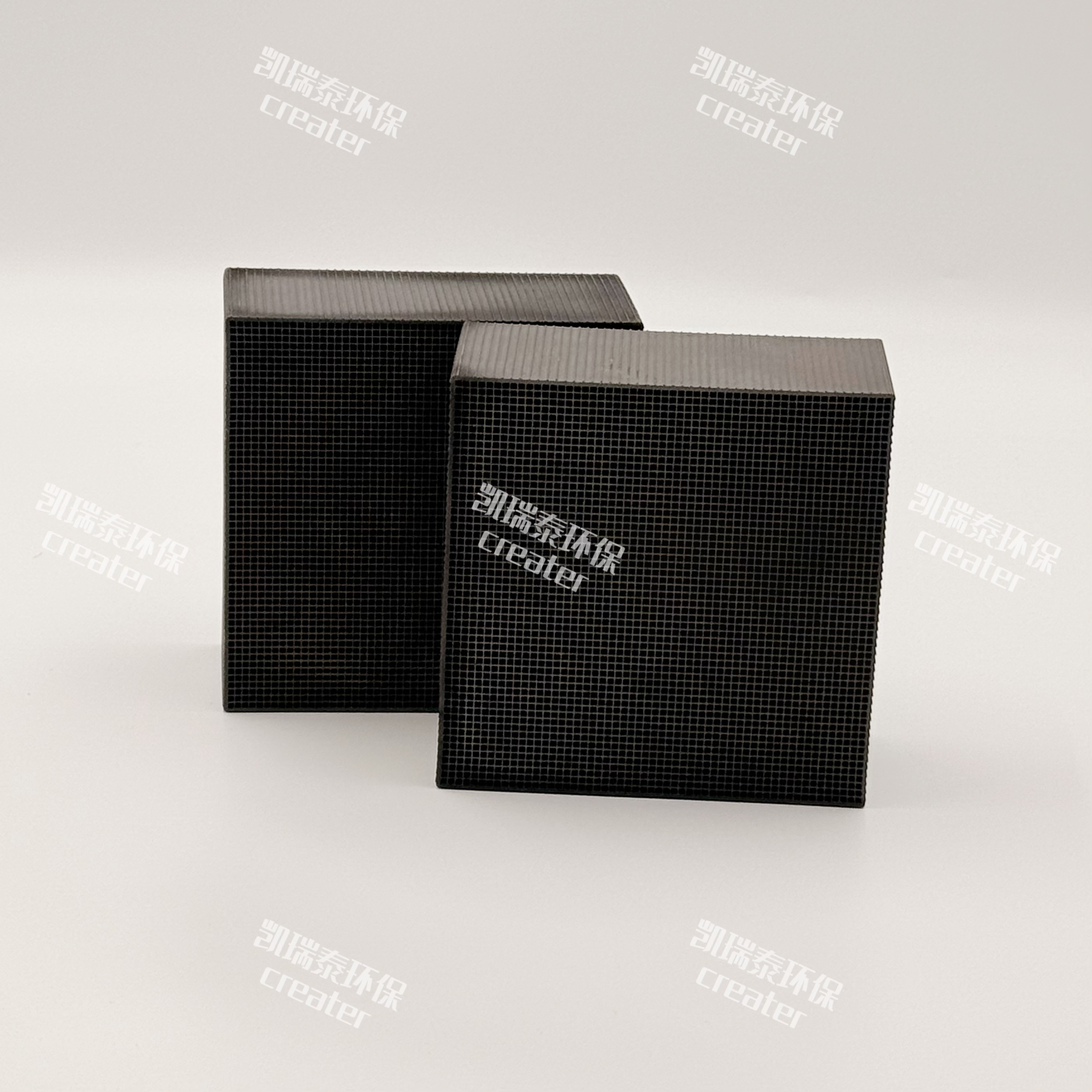

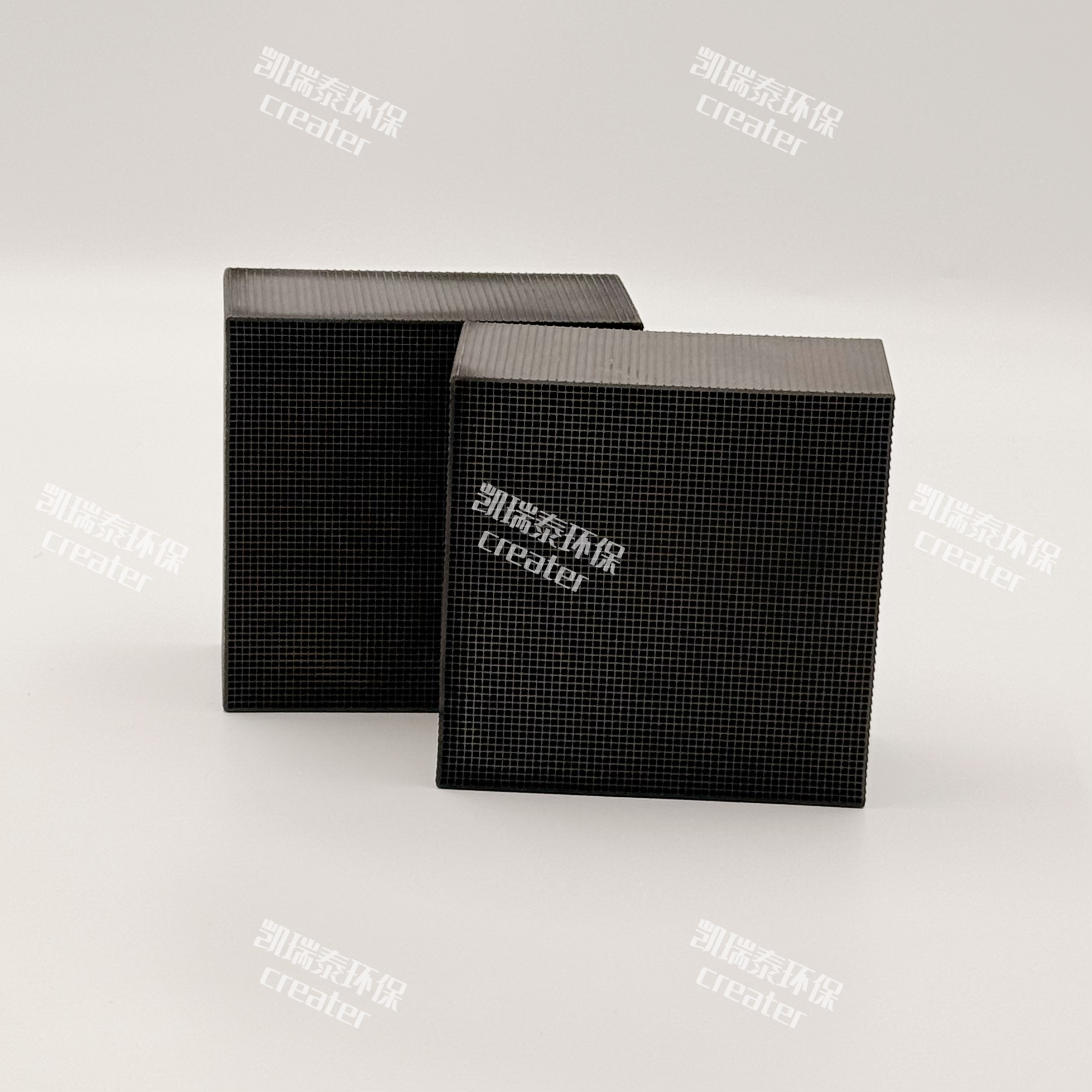

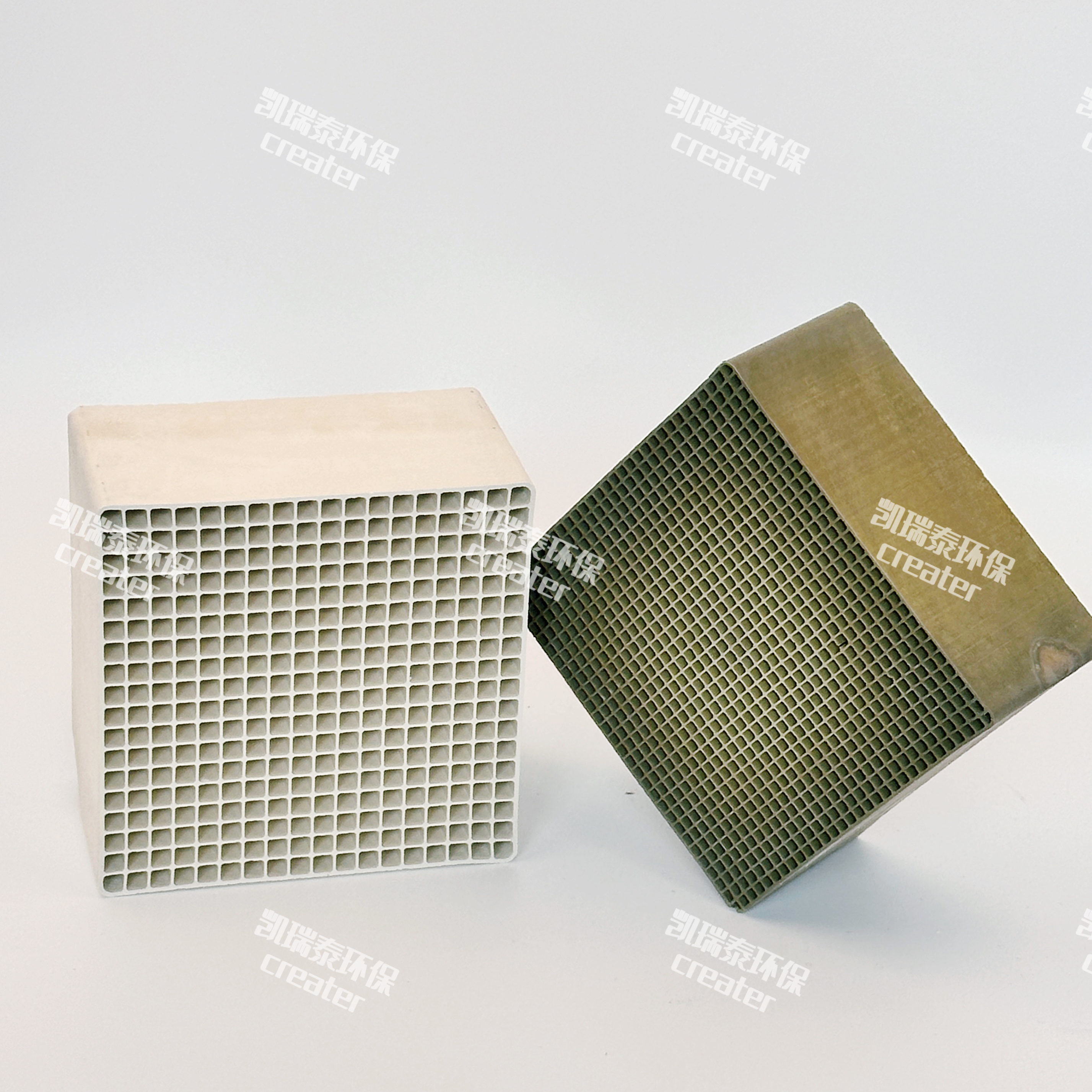

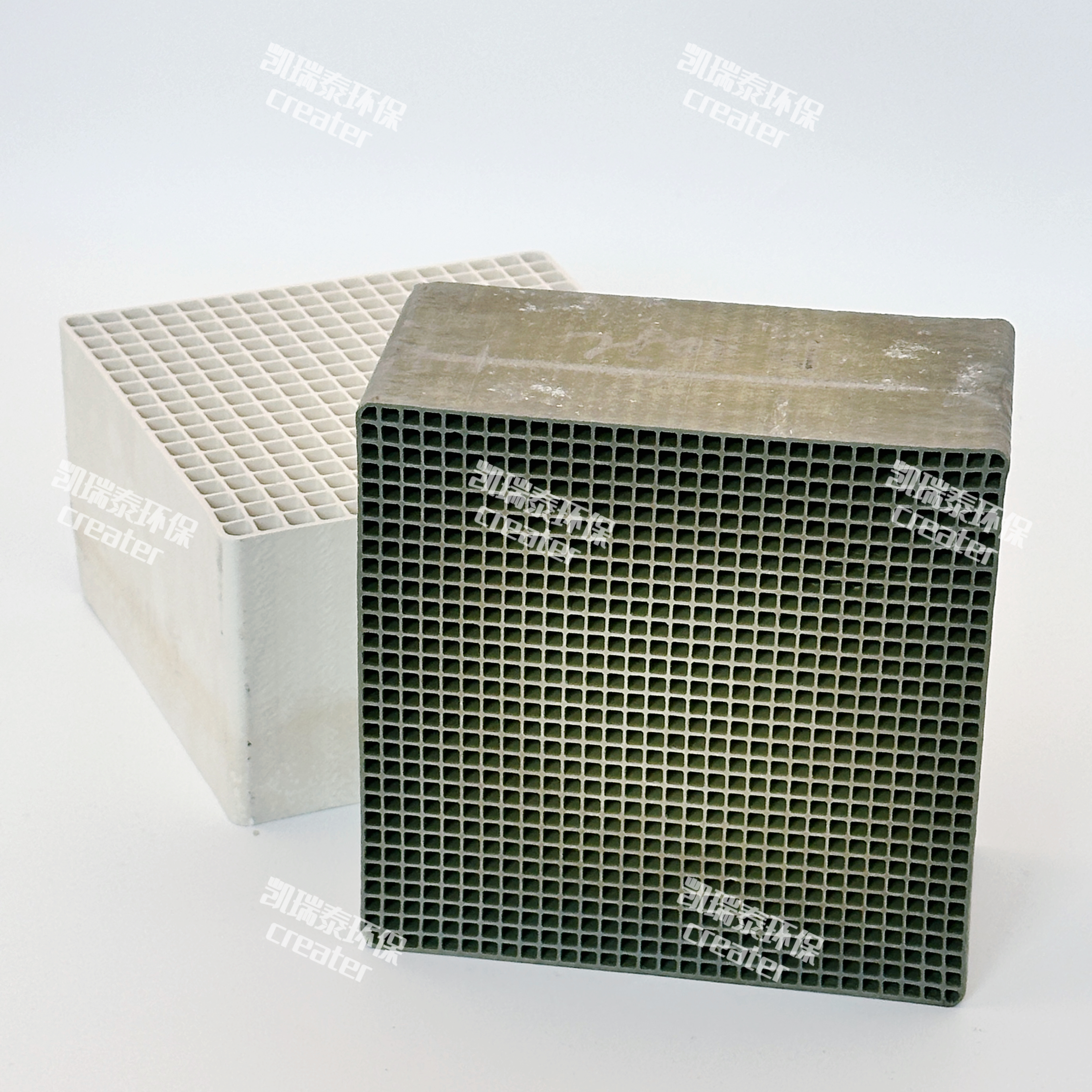

Integrated molding, with activity throughout the body;

Small volume, large specific surface area, high activity;

Catalytic active substances are 50-70% more than other types;

Strong ability to handle flue gas and high denitrification efficiency; SOz/SO3 conversion rate<1%, NH3 escape rate<3ppm;

The monomer adopts front-end hardening technology, which is resistant to erosion;

Wide applicable temperature range: 150 ℃ -420 ℃; The degree of production automation is high.

Reaction mechanism

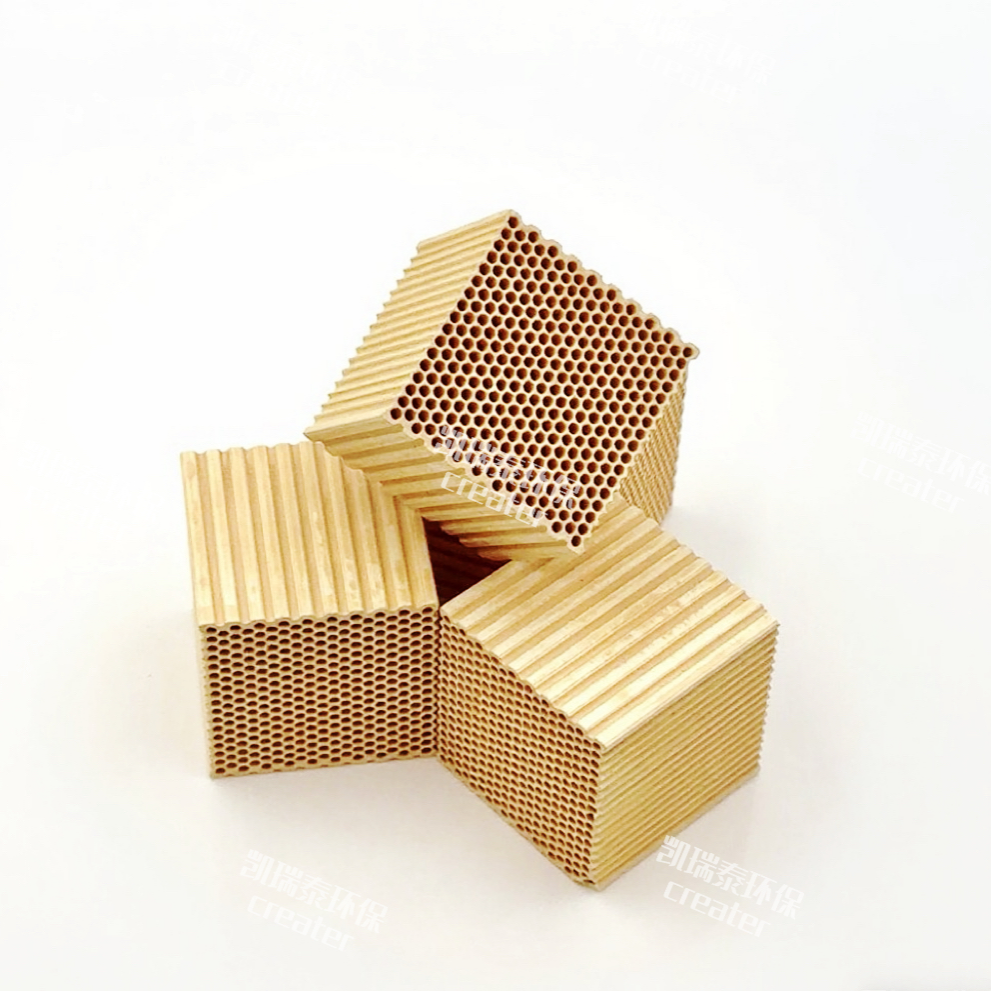

The raw flue gas from the kiln/boiler is first mixed with ammonia at 150-420 ℃. After being guided and rectified, the flue gas is evenly distributed. Then, it passes through a honeycomb type denitrification catalyst, and the mixed flue gas undergoes catalytic reaction on the catalyst surface to generate clean nitrogen gas and water. Finally, it is discharged or enters the next unit.

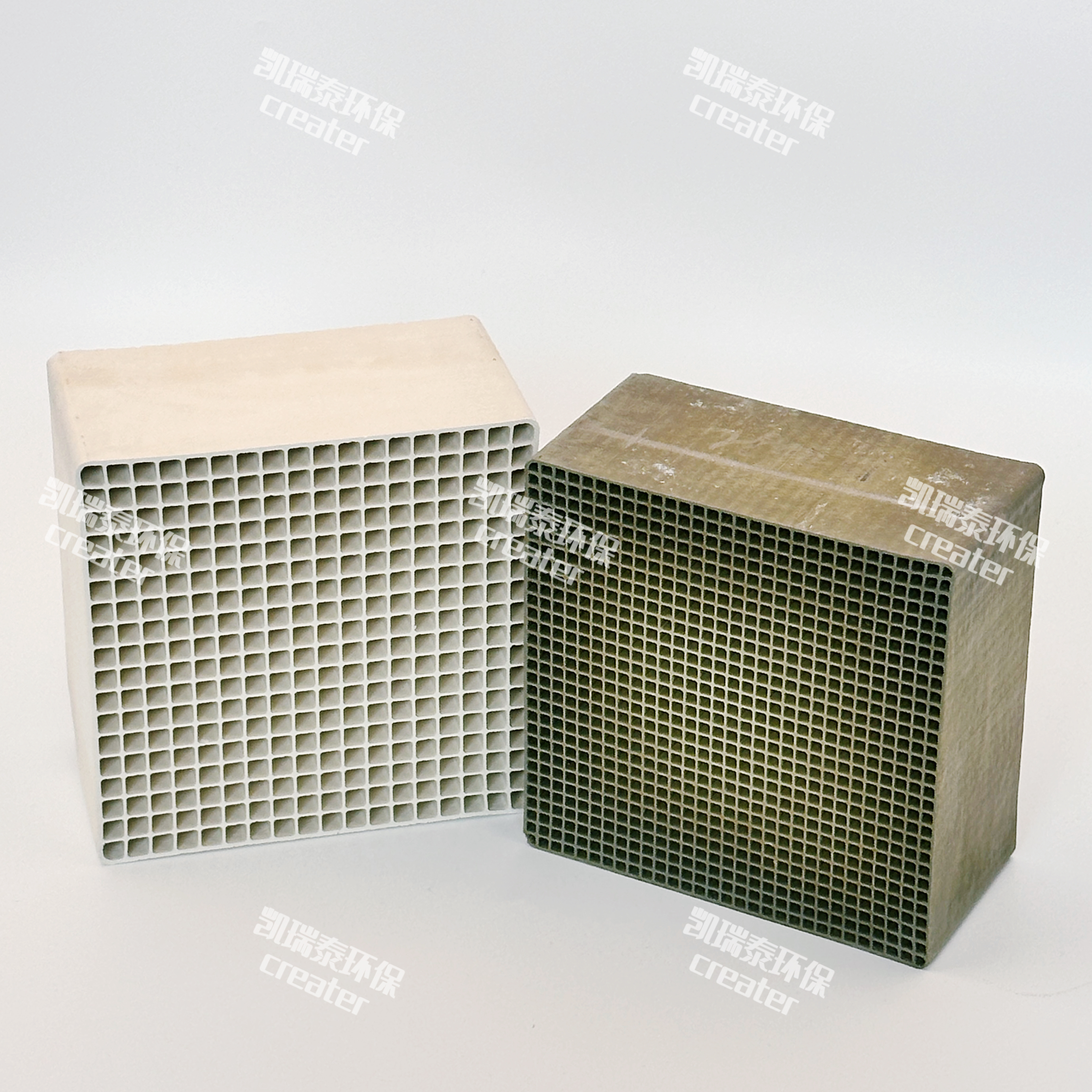

Performance comparison of different types of SCR catalysts

Application Industry

Steel industry - coking, sintering, pellet production

Municipal industry - waste incineration power generation, gas-fired heating boilers, hot spot cogeneration plants

Chemical and light industry - waste incineration, papermaking, acid washing, pharmaceuticals

Building materials industry - ceramics, refractory materials, glass, cement, lime

Nonferrous metallurgical industry - lithium industry, aluminum industry, magnesium industry, silicon industry

Transportation industry - ships, diesel engines, gas turbines